optris CTLaser Performance

optris CTLaser Performance

型號 : CTLaser LT/LTF/05M/1M/2M/3M(XL)/MT/F2/F6/G5/P7

數量 :

CTLaser Series – CTLaser LT(Fast)/05M/1M/2M/3M(XL)/MT/F2/F6/G5/P7

■ 德國Optris CTLaser系列高性能紅外測溫器雙雷射精確瞄準,最小量測點 1 mm

■ 堅固耐用不銹鋼測溫探頭及電纜可耐高溫達180°C的惡劣工業環境

■ 寬廣的測溫範圍 -50°C ~ 2200°C (switchable)

■ 光學解析最高達D : S = 300 : 1

■ 特定的測溫頻譜 8 ~ 14 μm(LT) / 2 . 3 μm(3M) / 1 . 6 μm(2M) / 1 μm(1M)

■ 反應時間最快速 1 mSec(1M/2M) / 6 mSec(LTF)

■ 類比訊號 0/4 ~ 20mA、0 ~ 10V、K或J型熱電偶輸出

■ 數位訊號 USB / RS232 / RS485(可串接32組) 等通訊介面 (選配)

■ 分離式I / O控制盒,具智慧LCD背光顯示

-

optris CTlaser LT / LTF

- optris CTlaser 05M

- optris CTlaser 1M / 2M

- optris CTlaser 3M

- optris CT XL 3M

- optris CTlaser MT

- optris CTlaser F2

- optris CTlaser F6

- optris CTlaser G5

- optris CTlaser P7

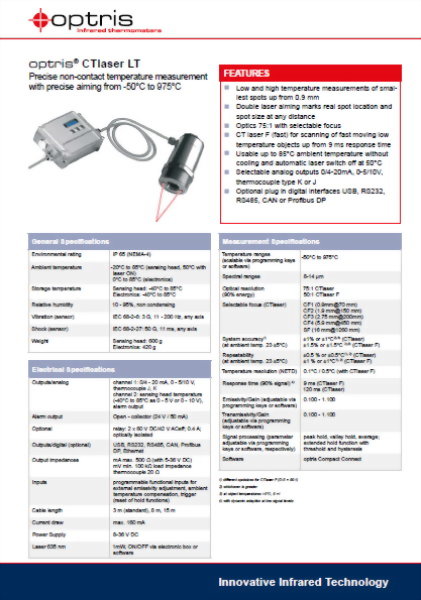

Technical Details of the optris CTlaser LT / LTF

- OPTCTLLT : -50 to 975 °C (-58 to 1787 °F) / 8 - 14 μm / 75:1 / 120 ms

- OPTCTLLTF : -50 to 975°C (-58 to 1787 °F) / 8 - 14 μm / 50:1 / 9 ms

Technical Details of the optris CTlaser 05M

Part number: temperature range / spectral range / optics / response time

- OPTCTL05M : 1,000 to 2,000°C (1832 to 3632 °F) / 525 nm / 150:1 / 1 ms

Technical Details of the optris CTlaser 1M / 2M

Part number: temperature range / spectral range / optics / response time

- OPTCTL1ML : 485 to 1050 °C (905 to 1841 °F) / 1.0 μm / 150:1 / 1 ms

- OPTCTL2ML : 250 to 800 °C (482 to 1472 °F) / 1.6 μm / 150:1 / 1 ms

- OPTCTL1MH : 650 to 1800 °C (1202 to 3272 °F) / 1.0 μm / 300:1 / 1 ms

- OPTCTL1MH1 : 800 to 2200 °C (1472 to 3992 °F) / 1.0 μm / 300:1 / 1 ms

- OPTCTL2MH : 385 to 1600 °C (725 to 2912 °F) / 1.6 μm / 300:1 / 1 ms

- OPTCTL2MH1 : 490 to 2000 °C (914 to 3632 °F) / 1.6 μm / 300:1 / 1 ms

Technical Details of the optris CTlaser 3M

Part number: temperature range / spectral range / optics / response time

- OPTCTL3ML : 50 to 400 °C (122 to 752 °F) / 2.3 μm / 60:1 / 1 ms

- OPTCTL3MH : 100 to 600 °C (212 to 1112 °F) / 2.3 μm / 100:1 / 1 ms

- OPTCTL3MH1 : 150 to 1000 °C (302 to 1832 °F) / 2.3 μm / 300:1 / 1 ms

- OPTCTL3MH2 : 200 to 1500 °C (392 to 2732 °F) / 2.3 μm / 300:1 / 1 ms

- OPTCTL3MH3 : 250 to 1800 °C (482 to 3272 °F) / 2.3 μm / 300:1 / 1 ms

Technical Details of the optris CT XL 3M

Part number: temperature range / spectral range / optics / response time

- OPTCTXL3MH : 100 to 600 °C (212 to 1112 °F) / 2.3 μm / 100:1 / 1 ms

- OPTCTXL3MH1 : 150 to 1000 °C (302 to 1832 °F) / 2.3 μm / 300:1 / 1 ms

- OPTCTXL3MH2 : 200 to 1500 °C (392 to 2732 °F) / 2.3 μm / 300:1 / 1 ms

- OPTCTXL3MH3 : 250 to 1800 °C (482 to 3272 °F) / 2.3 μm / 300:1 / 1 ms

Technical Details of the optris CTlaser MT

Part number: temperature range / spectral range / optics / response time

- OPTCTLMT : 200 to 1450 °C (392 to 2642 °F) / 3.9 μm / 45:1 / 10 ms

- OPTCTLMTH : 400 to 1650 °C (752 to 2912 °F) / 3.9 μm / 45:1 / 10 ms

Technical Details of the optris CTlaser F2

Part number: temperature range / spectral range / optics / response time

- OPTCTLF2 : 200 to 1450 °C (392 to 2642 °F) / 4.24 μm / 45:1 / 10 ms

- OPTCTLF2H : 400 to 1650 °C (752 to 2912 °F) / 4.24 μm / 45:1 / 10 ms

Technical Details of the optris CTlaser F6

Part number: temperature range / spectral range / optics / response time

- OPTCTLF6 : 200 to 1450 °C (392 to 2642 °F) / 4.64 μm / 45:1 / 10 ms

- OPTCTLF6H : 400 to 1650 °C (752 to 2912 °F) / 4.64 μm / 45:1 / 10 ms

Technical Details of the optris CTlaser G5

Part number: temperature range / spectral range / optics / response time

- OPTCTLG5L : 100 to 1200 °C (212 to 2192 °F) / 5 μm / 45:1 / 120 ms

- OPTCTLG5H : 250 to 1650 °C (482 to 2912 °F)/ 5 μm / 70:1 / 80 ms

- OPTCTLG5HF : 200 to 1650 °C (392 to 2912 °F) / 5 μm / 45:1 / 10 ms

Technical Details of the optris CTlaser P7

Part number: temperature range / spectral range / optics / response time

- OPTCTLP7 : 0 to 710 °C (32 to 1310 °F) / 7.9 μm / 45:1 / 150 ms