首頁 »

產品介紹 » Optris 歐普士 » Optris 手提式紅外線測溫器 »

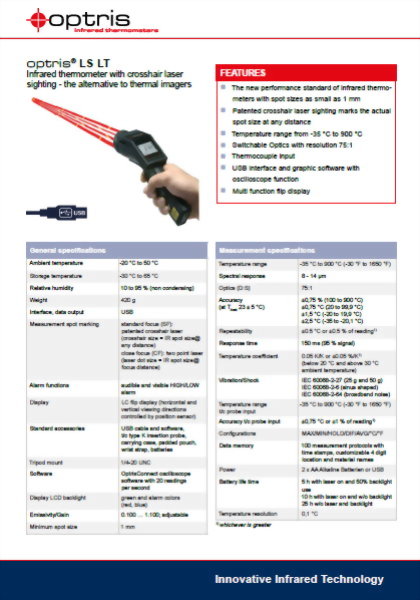

optris LS LaserSight

optris LS LaserSight

LaserSight Series - LS

■ 手提式 LS (含標準器 LS-DCI1) 2018年底停產,訂單只接到2018年10月1日止

■ 德國Optris LS國際專利LaserSight雙鏡頭切換

■ 同軸雷射設計可準確顯示實際測量範圍大小

■ 紅外線溫度計光學的創新,最小可測 1mm的目標

■ 螢幕倒置自動切換方向,測量微小目標物時讀值更準確

■ 測溫範圍 -35°C ~ 900°C

■ 測溫頻譜 8 ~ 14 μm

■ 光學解析 D:S=75:1(SF:16mm@1200mm) / 60:1(CF:1mm@62mm)

■ 反應時間 150 mSec

■ 雷射瞄準 同軸十字雷射 (SF)/聚焦交叉雷射(CF)

■ 測溫精確度 ±0.75% 或 ±0.75°C (讀值取大值)

■ 測溫重複性 ±0.50% 或 ±0.50°C (讀值取大值)

■ 高/低溫警報(視覺及聲響)

■ 外接熱電偶 Type K 輸入功能

■ 100組資料存儲功能,並可通過數位介面連至PC進行資料分析

■ 數位通訊 USB介面與軟體,每秒取樣頻率高達20次

Technical Details of the optris LS LT

Part number: temperature range / spectral range / optics

- OPTLS : -35 to 900 °C (-31 to 1652 °F) / 8-14 μm / 16 mm @ 1200 mm (0.63 in @ 47.24 in) (75:1)

Application examples for non-contact temperature measurement

Temperature measurement and 3D laser scanning

Temperature measurement in automotive industry

Temperature measurement for fire prevention

Temperature measurement in plastics industry

Temperature measurement in life science / medical

Temperature measurement in solar / semiconductors industry

Temperature measurement in metal industry

Temperature measurement in glass industry

Temperature measurement in maintenance

相關產品

optris MS MiniSight

Model : MS/MS+/MSpro

© 2026 紅點量測有限公司 All rights reserved.